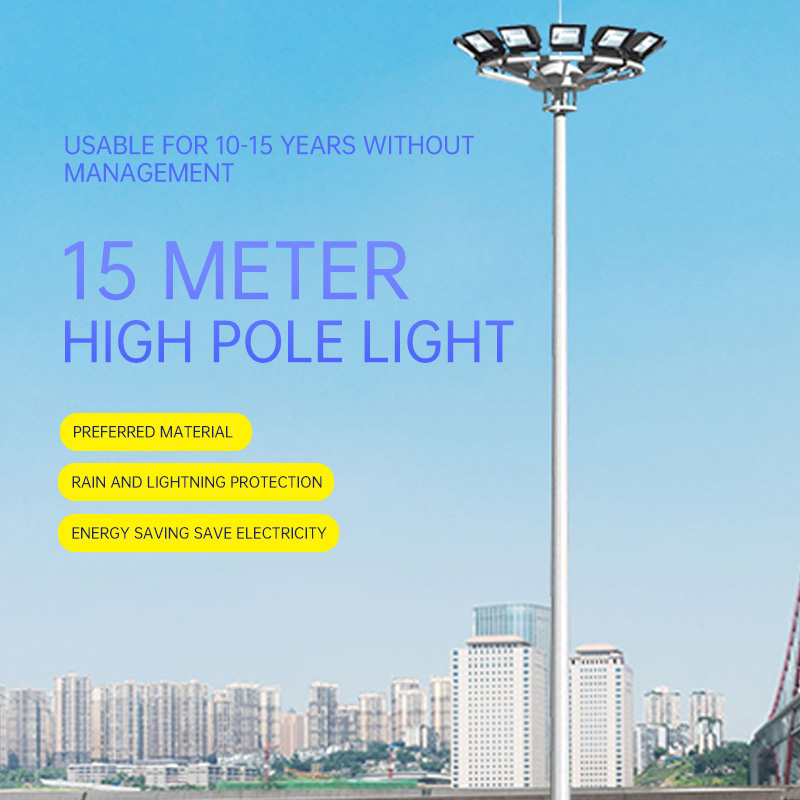

15m High Pole Lamp, The Number Of Lamps Is Optional, Support Customization

2022-08-05

2022-08-05

Application places: urban leisure plazas, park plazas, scenic plazas, railway stations, high-speed railway stations, docks, logistics and freight plazas, etc. Using anti-corrosion hot-dip galvanizing technology, the pole body of the lamp is polished and pickled to remove the surface welding slag and rust, and then immersed in a galvanizing pot, so that the surface of the pole body is evenly attached with a thick enough zinc layer, which can be used in outdoor environments all year round.

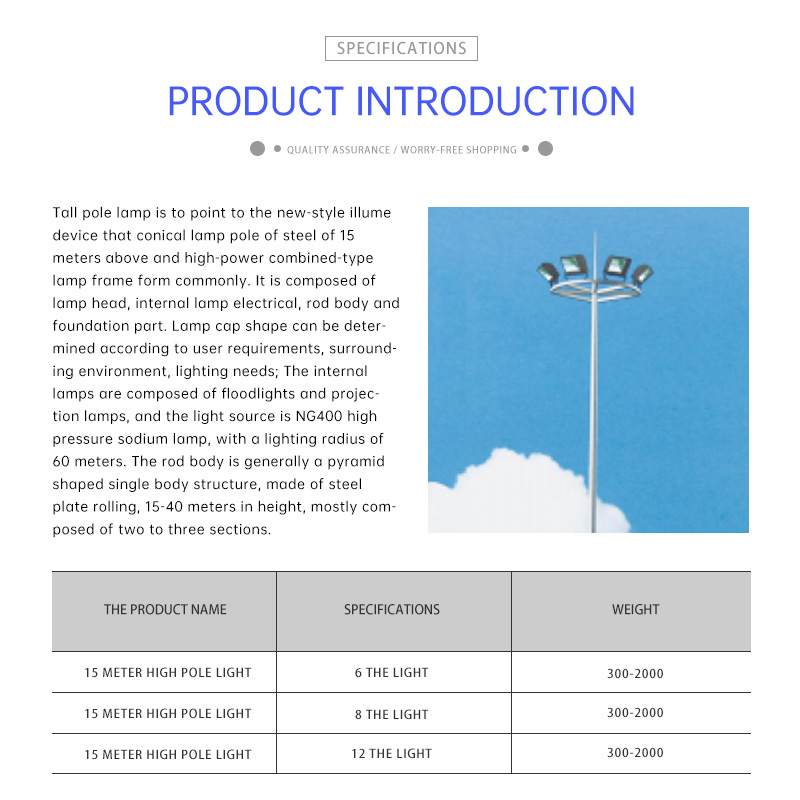

A new type of lighting device composed of a steel cone light pole over 15 meters and a high-power combined light frame. It is composed of lamp holder, internal lamp electrical, rod body and basic part. The shape of the lamp head can be determined according to the user's requirements, the surrounding environment, and the lighting needs; the internal lamps are mostly composed of floodlights and floodlights, and the light source is NG400 high-pressure sodium lamps, with a lighting radius of 60 meters. The rod body is generally a pyramid-shaped single-body structure, rolled with steel plates, with a height of 15-40 meters, and is mostly composed of two to three sections.

Chongqing Yudai Road Industrial Technology Co., Ltd. was established in July 2016. Mainly engaged in hot-dip galvanizing of metal materials, spraying surface treatment, processing and manufacturing of steel structure products, etc. The company currently has a production workshop of 20,000 square meters, with advanced equipment such as CNC flame cutting machines, shearing machines, and angle steel production lines. The company has newly built two hot-dip galvanizing production lines, with an annual galvanizing production capacity of 200,000 tons and a 15.4-meter-long galvanizing pot, which can meet the needs of most customers. Two steel structure processing production lines have been built and put into operation, one is an ordinary steel structure processing production line, which mainly produces various lattice-type steel columns, three-pipe towers, pipe beams, columns, and suspenders for communication, electric power, and railways, and can also process communication towers. , outdoor lighting poles, sign poles, steel structure workshops; another special production line can produce buckle-type scaffolding, highway anti-collision brackets and other products, forming a production capacity of steel structure processing with an annual output of more than 30,000 tons.

Yongdan Shi

417126511@qq.com