1. DC resistivity: the resistivity of copper clad aluminum wire is larger than that of pure copper wire, about 1.5 times of that of pure copper wire. When the negative value is the same, the weight of copper clad aluminum wire is about 1/2 of that of pure copper wire. According to the calculation of skin effect, when the high frequency is above 5MHz, the resistivity is equal to that of copper conductor with the same section. In the use of 50Hz power cables, the skin effect and proximity effect of copper conductors become increasingly prominent when they are more than 150 mm. At the same time, due to the continuous development of science and technology, high-order harmonic currents and energy will be injected into the power supply system, and high-order harmonic voltages of corresponding frequencies will be generated on the impedance of the system, resulting in distortion of the voltage waveform, increased loss of the power supply system, and increased conductor heating; In addition, the cable amplifies the harmonic wave, causing overvoltage at the joint and damaging the cable head. The use of copper clad aluminum conductor will reduce the AC impedance (resistance) generated by high order harmonics. In other applications, the volume of copper in the copper clad aluminum monofilament and corresponding process measures are taken to make the copper clad aluminum/copper composite conductor meet the requirements of conductor DC resistance within the upper limit of the outer diameter of the existing conductors of the same specification.

2. The use of copper clad aluminum conductor can meet the current habit of wire and cable in product selection, design, use, installation, etc., which will be continued for many years. It is also beneficial to the cable terminal compression and tin welding.

3. Reduce AC resistance:

(1) AC resistance is the main basis of current carrying capacity. According to the principle of skin effect, the current passing through the surface of a single conductor per unit area is larger than the current passing through the center of the conductor per unit area, that is, the center of the conductor with large cross section is in the circular area formed by the same conductor, and the current passing through the center is smaller than the current passing through the circumference. Therefore, it is most reasonable to use different metals to form the center conductor and the circumference conductor The most economical.

(2) In addition to DC resistance and skin effect, AC resistance indexes are affected by proximity effect. Compared with copper conductors with the same DC resistance, after using copper composite conductors, aluminum is at the center of the circle and copper is at the outer edge of a single conductor; In the twisted conductor, the inner layer is copper clad aluminum, and the outer layer is pure copper, while aluminum is not sensitive to skin effect and proximity effect. At the same time, the copper composite conductor will increase the total cross-section of the conductor, so it also increases the surface area of the conductor, improves the heat dissipation condition of the cable, and increases the heat dissipation area. While the thermal conductivity of aluminum is similar to that of copper, under the same material cost conditions, the AC resistance index is much more economical.

4. Good corrosion resistance: aluminum is more susceptible to corrosion than copper, but since the copper clad aluminum material has been fully metallized, aluminum is completely covered by copper, and will not be exposed to water and air, completely achieving the same performance as copper. Copper clad aluminum/copper composite conductor is also more conducive to avoiding the hidden danger of poor contact between conductor and terminal due to corrosion, bruise, or poor compaction and tin welding during long-term use of cable, copper layer falling off due to heating, and potential difference between copper and aluminum, which accelerates electrochemical corrosion and causes cable end burning. For aluminum conductors, especially in coastal areas, chloride ions contained in salt spray in the atmosphere will condense on the surface of aluminum, which is easy to cause local corrosion around impurities and defects on the surface, forming holes, cracks and micro cells, and intensifying the corrosion of aluminum conductors.

5. Low cost and light weight: Compared with copper core cables with the same technical indicators, copper clad aluminum conductor cables can save more than 40% of the cost, and copper clad aluminum/copper composite conductor cables can save more than 20% of the cost. The proportion of copper clad aluminum wire is only 37% - 40% of that of pure copper wire. When the wire diameter and weight are equal, its length is 2.5 times that of pure copper wire.

6. Good weldability: As the surface of copper clad aluminum wire is concentrically coated with a layer of pure copper, it has the same weldability as pure copper wire and is convenient for production.

Due to the high cost of pure copper, copper clad aluminum has been used in coaxial cables and power lines in recent years. Copper clad aluminum wire adopts the cladding welding manufacturing technology. The high-quality copper strip is concentrically coated on the outer surface of the core wire such as aluminum rod or steel wire, and forms a solid metallurgical combination between the copper layer and the core wire, so that two different metal materials can be combined into an indivisible whole. It can be drawn and annealed like processing a single metal wire. During the drawing process, copper and aluminum are reduced in the same proportion, The volume ratio of copper layer remains relatively constant.

Copper clad aluminum cable refers to the wire and cable with aluminum core wire instead of copper as the main body of the cable and covered with a certain proportion of copper layer.

Copper clad aluminum cables can be basically divided into two categories according to their applications: one is copper clad aluminum cables for signal or communication purposes, and the other is copper clad aluminum cables for power supply.

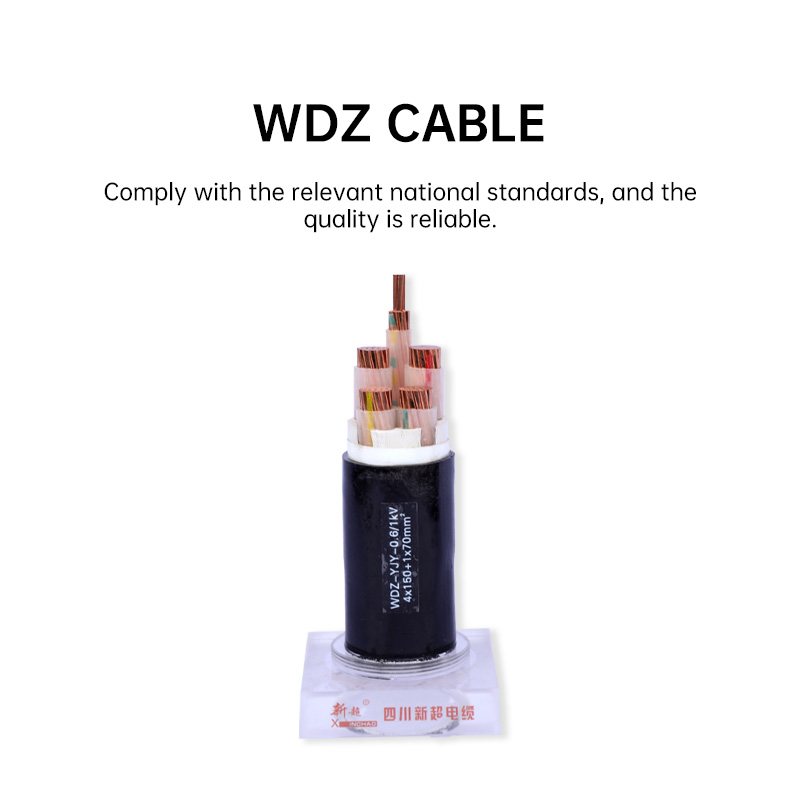

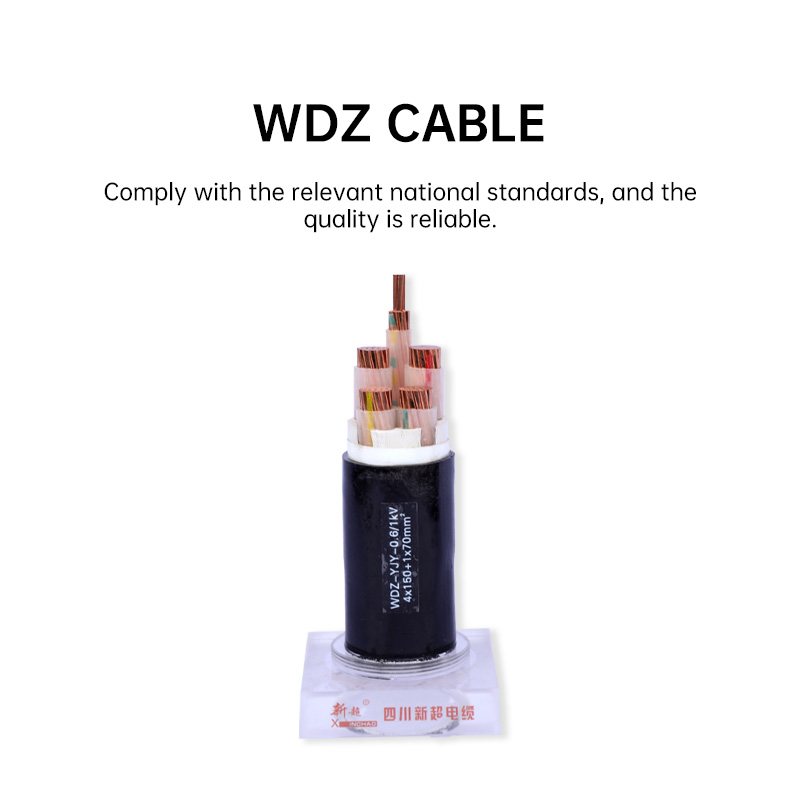

Sichuan Xinchao Cable Co., Ltd. is a professional manufacturer and service provider specializing in the production and sales of wires, cables and accessories. The company is located in Tanjiachang Industrial Zone, Lichun Town, Pengzhou City, Sichuan Province, adjacent to Chengpeng Expressway, Chengdu Second Ring Expressway and Chengguan Expressway. The company covers an area of 360,000 square meters, with 180 employees, 36 middle and senior professionals, and 110 million yuan in fixed assets. There are 28 cable production lines, more than 60 sets of high and low voltage cable production equipment, more than 20 sets of various inspection equipment, and other supporting equipment. The annual production capacity exceeds 1 billion yuan. It is a large-scale comprehensive enterprise integrating scientific research, development, production and sales. .

Since its establishment, the company has grown in scale, has advanced production lines and testing equipment, strictly follows standards and organizes production, and implements full monitoring from the purchase of raw materials to the delivery of finished products. Formulate the quality policy of "focusing on customer needs, based on production management, continuously improving the quality system, and improving customer satisfaction products".

The company has passed the ISO9001:2015 quality management system certification, ISO14001:2015 environmental management system certification, OHSAS18001:2007 occupational health and safety management system certification, and obtained the production license issued by the General Administration of Quality Supervision, Inspection and Quarantine, CCC certification, and flame retardant products in public places. Use certificate, safety production standardization certificate and won many honorary titles such as "National Customer Satisfaction Products, National Authoritative Testing Quality Products, China Green Environmental Protection Products, and China Famous Brands". It is well received and trusted by partners and users.

Facing the new market competition trend and the pattern of economic integration, Xinchao Cable will adhere to the development concept of "quality determines strength", adhere to the business policy of "honesty, innovation, forge ahead, and steady development, and vigorously promote technological innovation. , capital operation, and three major strategies for expansion, to promote the transformation of Xinchao Cable from a traditional enterprise to a high-tech industry, and to contribute our wisdom and strength to the construction of the power industry.

Mr. Cao

1210994309@qq.com

※FIND US※

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

2022-11-28

2022-11-28