Flame Retardant Expanded Polystyrene Board (EPS)

2023-03-13

2023-03-13

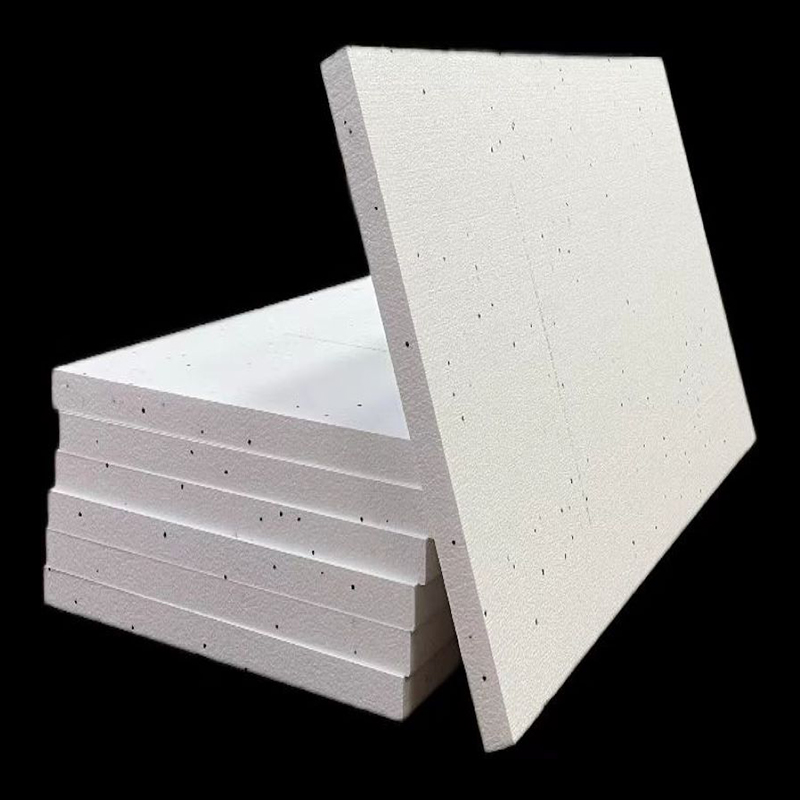

EPS polystyrene board is an abbreviation for expanded polystyrene foam board. It is made by pre-processing, maturing, molding, drying, and cutting polystyrene raw materials.

Mainly used for:

1. Insulation layer for building walls, roof insulation and composite insulation panels;

2. Insulation materials for vehicles, ship refrigeration equipment and cold storage;

3. Used for decoration and carving various models.

4. Used as a protective layer for waterproof layers.

Characteristics of flame retardant expanded polystyrene boards

1. Good heat-insulating and energy-saving effects

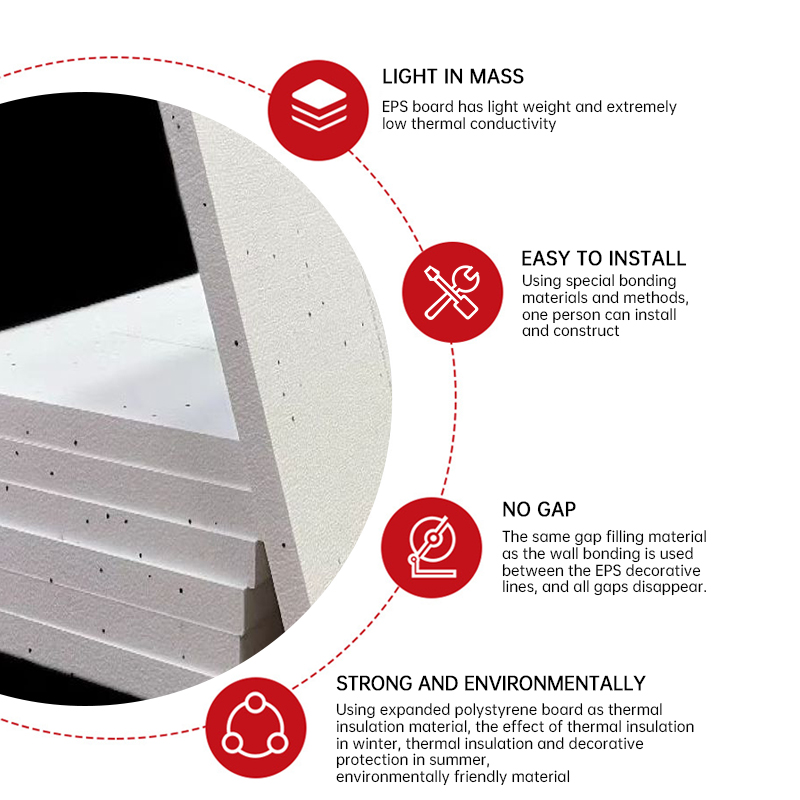

Flame retardant expanded polystyrene sheets continue the advantages of traditional EPS foam boards with low thermal conductivity and high heat storage coefficient, and have better insulation effects than inorganic active insulation mortars and foam glass on the market.

2. Safety and fire protection - grade A flame retardant materials

Overcoming the shortcomings of traditional EPS foam boards that are flammable, the safety performance is very high.

3. Class A fireproof EPS insulation board has higher strength than rock wool and phenolic boards. It does not absorb water, does not fall off, and is easy to construct.

4. Excellent system performance

It is a closed and foamed spherical molecular structure. It is relatively light in weight, has good dimensional stability, and is non-toxic. The system has been tested for weatherability, that is, after 80 high-temperature-sprinkling cycles and 30 heating-freezing cycles, the finish layer did not bubble, empty or fall off, and there were no water seeping cracks. The impact resistant tiles reached 10J, and the impact-resistant paint reached 10J, and the performance was superior.

5. Mature process

The construction process is the same as that of traditional EPS thin-plastered exterior wall insulation systems. The construction process is mature, easy for workers to construct, safe and reliable, and there are no unstable defects in other novel material systems.

6. Excellent price/performance ratio

It retains the advantages of “low thermal conductivity, good insulation effect, and mature process” of traditional EPS foam boards, and is low in cost. The price is far lower than similar grade A flame retardant insulation materials on the market. The effect of grade A flame retardant is obtained at the price of ordinary materials. The cost performance ratio is superior, and the market prospects are broad.

Chongqing Ruilong foam plastic Co., Ltd. was established in 1995. It has more than 80 employees, including 8 middle and senior professional and technical personnel. The company is located in Jinglong Industrial Park, Hangu Town, Jiulongpo District, Chongqing. It covers an area of 20000 ㎡, with a designed annual consumption of 6000 tons of EPS and XPS raw materials and an annual output of 350000 M ³ Finished plate. The company is a large-scale processing enterprise specializing in the production of (EPS) expanded polystyrene board and (XPS) expanded extruded board in Southwest China. The company's products are mainly used for industrial casting. In addition, they are also widely used for wall insulation, exterior wall decoration lines, freezing and cold storage, shockproof and sound insulation.

Pioneering, innovative and enterprising is the enterprise's purpose. At the end of 2011, the company introduced advanced production equipment from South Korea. Which greatly improves the solubility and compressive strength of the product. After years of research and development, the company has formed a stable product production system and process parameters, which greatly improves the stability of products. In the production process, the whole process real-time monitoring is adopted to strictly control and improve the product quality. The lost foam white film produced by the company has the characteristics of good fusion bonding, high compressive strength, low water content and no shrinkage deformation, which fully meets the requirements of automatic digital milling processing of lost foam. With excellent product performance, the lost foam white film produced by the company has successfully occupied 80% of the market share in Southwest China, covering Sichuan, Hubei, Hunan and other surrounding provinces.

The board produced by the company is widely used in the building industry and is the traditional preferred material for energy conservation and insulation. In October 2010, it passed the Chongqing building energy conservation technology filing. In February 2011, it obtained the certification of building energy conservation technology (product) of Chongqing Construction Technology Development Center.

Since its establishment, the company has adhered to the business philosophy of "brand comes from quality and reputation shapes the future", adhered to honesty, brand strategy as a means, customer satisfaction as a goal, and constantly exceeded itself to achieve continuous breakthroughs in product quality.

Contact Person:He Zhenni

Email:506324472@qq.com