SCRAP PUNCHING MACHINE

2023-06-30

2023-06-30

Stamping is a forming process that relies on presses and dies to apply external forces to plates, strips, pipes and profiles to produce plastic deformation or separation to obtain workpieces of the desired shape and size (stamped parts). Stamping and forging are both plastic processing (or pressure processing) and are collectively called forging. The blanks for stamping are mainly hot-rolled and cold-rolled steel plates and strips. Of the world's steel, 60-70% are plates, most of which are made into finished products after stamping. The body, chassis, fuel tank and radiator sheet of automobile, steam ladle of boiler, shell of container, silicon steel sheet of iron core of motor and electric appliance are all stamping process. There are also a large number of stamping parts in products such as instruments, household appliances, bicycles, office machinery, and living utensils.

1. Stamping is a processing method with high production efficiency and low material consumption. The stamping process is suitable for the production of large quantity of parts and products, which is convenient for mechanization and automation and has high production efficiency. At the same time, stamping production not only strives to achieve waste less and waste free production, but also makes full use of the edge and corner remnants even in some cases.

2. The operation process is convenient and does not require a high level of skill of the operator.

3. The parts produced by stamping generally do not need to be machined again and have high dimensional accuracy.

4. Stamping process can obtain parts with high strength, high stiffness and light weight.

5. The cost of stamping parts produced in mass production with dies is low.

6. Stamping can produce parts with complex shapes that are difficult to be processed by other metal processing methods.

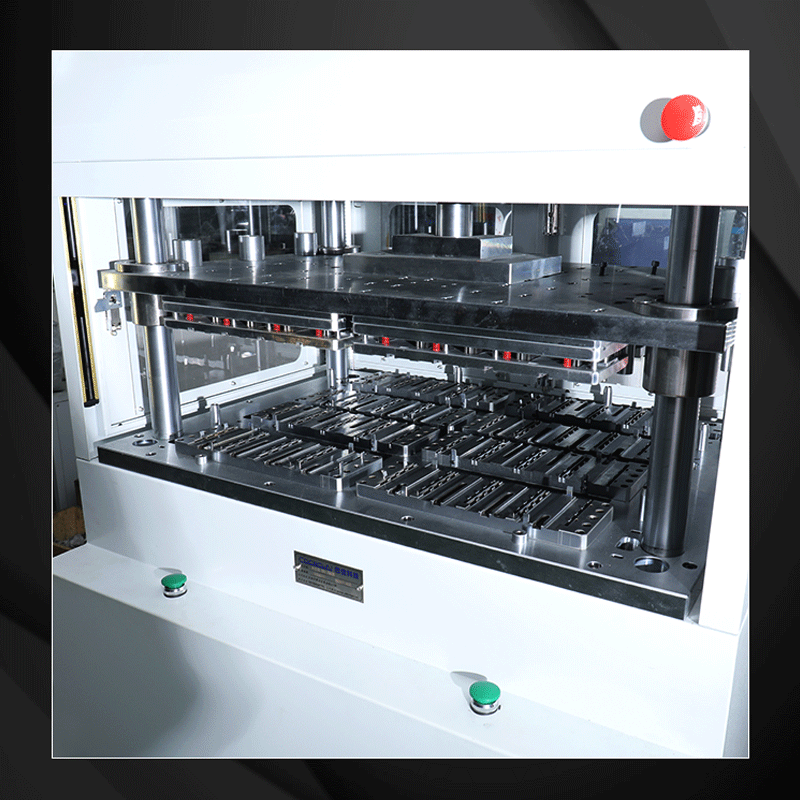

Punching and scrap discharge machine is an automatic machine and equipment whose main function is to press, bend and shear the sheet several times and automatically discharge the scrap so as to process the finished product. The working principle of the stamping and scrap removal machine is that the sheet to be processed is placed on the working table and then pressed and operated several times by the die on the press to finally cut the material into the desired shape, while the scrap is automatically removed in the process. With its rich functions and flexible adaptability, the press excludes scrap in one machine, which is widely used in various industries, such as automotive, electronics, home appliances, construction, etc. Its advantages are high efficiency, human resource saving, and high precision.

The stamping process can be divided into four basic processes:

Punching: The stamping process that enables the separation of the sheet (including punching, dropping, trimming, cutting, etc.)

Bending: The stamping process of bending the sheet into a certain angle and shape along the bending line.

Deep drawing: A stamping process that turns a flat sheet into various open hollow parts, or further changes the shape and size of hollow parts.

Partial forming: Stamping process to change the shape of blank or stamped part by various partial deformation of different nature (including flanging, expanding, leveling and shaping process, etc.)

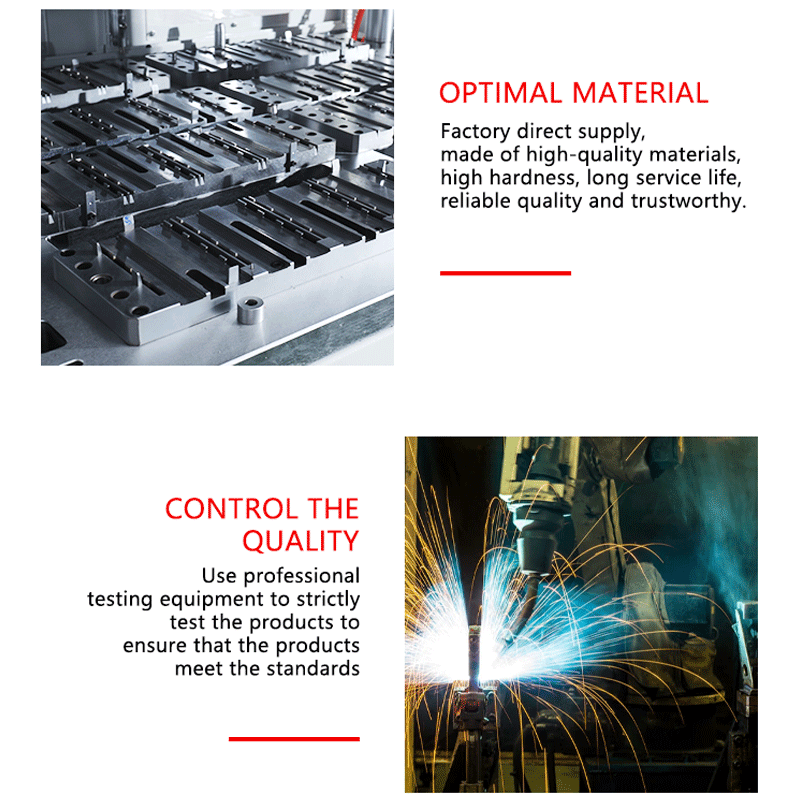

Sichuan sijia technology co., ltd. Was established in august 2017. It is a comprehensive service company specializing in the research, development, design, manufacturing and sales of ic semiconductor packaging molds, cutting and punching molds, semiconductor automatic equipment, precision electronic machinery parts and other products, as well as technical consulting and technical services in related fields, and has independent import and export management rights for science, industry and trade. It is the first rectifier device factory in the west to introduce the latest production equipment and processes in the world today, and promote the development of the semiconductor industry in the western region with high-tech products.

Corporate purpose:

To customers: Win-win cooperation and common growth;

To shareholders: Highly responsible and long-term return;

To society: Responsibilities and obligations to give back to the public;

Treating employees: Learning and training, self-accomplishment;

Enterprise mission: Four best in one hundred years; strengthen chinese manufacturing industry and promote chinese mould and mould industry; provide excellent quality products and promote fine product concept; promote quality service for customers' products; build a realization platform for employees' life value.

We have adopted the international advanced cad/cam/cae computer aided design and analysis software, which can quickly analyze the product forming process, predict the form and location of product defects, and take measures during design to avoid product defects and ensure the scientificity, reliability and economy of the design.

Zou Lihua

yyl20221104@163.com