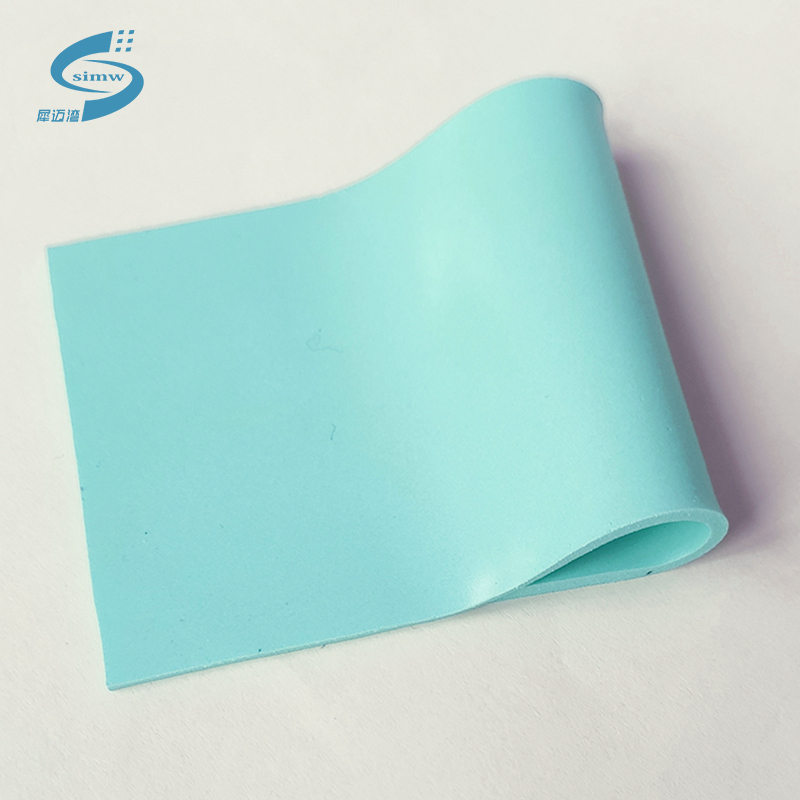

Thermal Conductive Silicone Pad

2022-05-09

2022-05-09

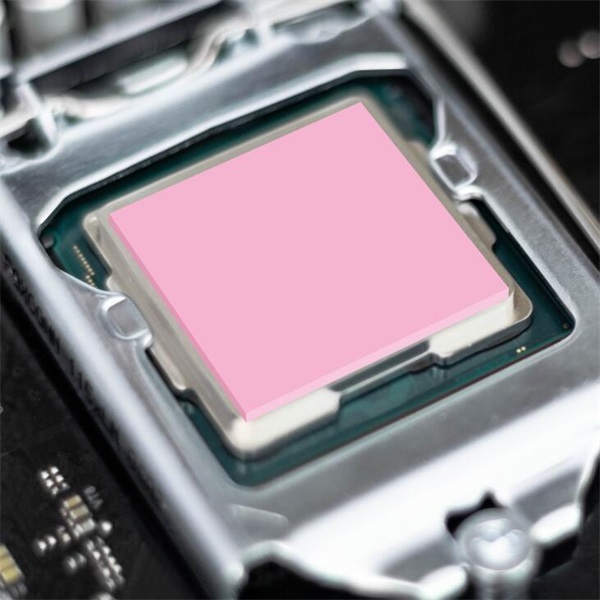

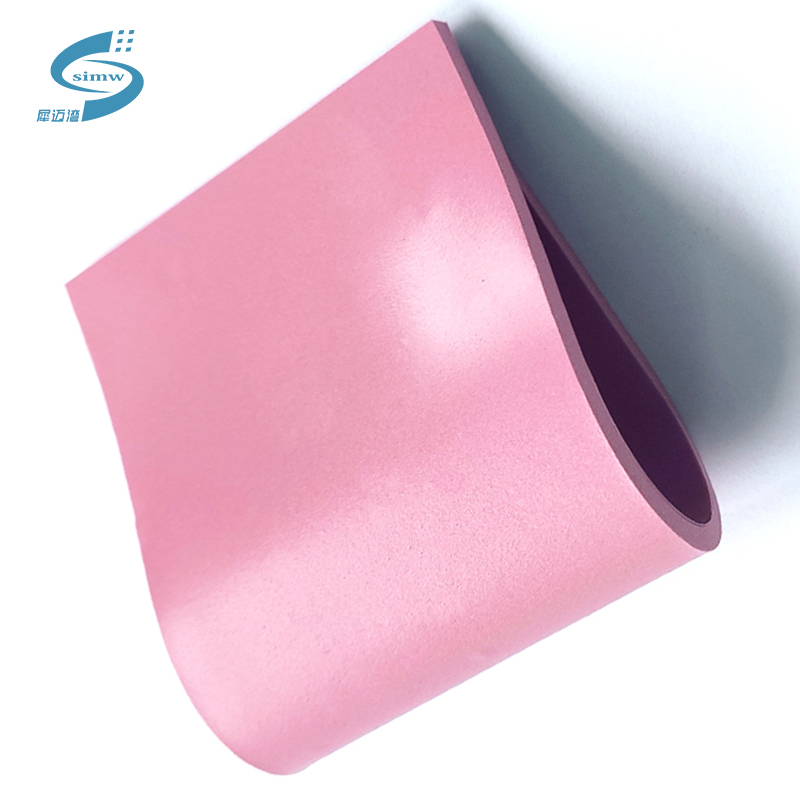

Thermal conductive silicone pad, with high thermal conductivity of ceramic powder and silicon rubber as the main raw material, made by the vacuum blend and in-situ polymerization process to finalize the design of thermal conductivity composite material, has excellent thermal conductivity, insulation, mechanical resistance, aging resistance, high and low temperature performance, green environmental protection, comply with RoHS requirements, can effectively fill the gap, reduce the interface thermal resistance, promote heat transfer, And take into account shock absorption, sealing and other multiple functions. Each parameter is adjustable, can be customized according to customer needs, to achieve the best use effect.

Application of thermal conductive silicone sheet: With the popularity of chip and lithium battery application scenarios, heat dissipation has become an important bottleneck restricting product performance. Thermal conductive silicone gasket is widely used in security, LED, CPU, power supply, automotive, household appliances, new energy, computer, consumer electronics, integrated circuits, communication equipment, industrial control equipment, power semiconductor and other fields.

Simw thermal conductive silicone pad: made of high thermal conductive filler and organic silicon has good thermal conductivity, insulation, mechanical resistance, aging resistance, high and low temperature performance, used in mobile phone, chip, light source, power supply, lithium battery, super capacitor, CPU, LED, IGBT, cars, cameras, transformer, flat, radio frequency devices, industrial control equipment of heat and cooling. You can customize the parameters as required to achieve the best use effect.

Sichuan Ximaiwan Technology Co., Ltd. is a research and development, manufacturing, sales as one of the new material technology company. To meet the needs of high-quality thermal management in the fields of chips, communications, security, home appliances, automobiles, light sources, power supplies, buildings, integrated circuits, weapons and equipment, we provide customers with industry-leading thermal management products and technical services such as thermal conductivity, heat storage, heat dissipation, temperature regulation, energy saving and so on.

Headquartered in Chengdu, the production base is located in the Sino European Industrial Park in Qingbaijiang, Chengdu, covering an area of 2500 square meters. It has 3 automatic heat conducting silica gel production lines, and the testing and testing equipment is complete. It is the largest and the most powerful thermal power development and production base for silica gel, gel and graphene thermal conductive plastics in Southwest China. The company's main technology comes from Tianjin University of technology, Hong Kong University of science and technology, Nanyang Technological University of Singapore and other well-known universities at home and abroad. The core R & D team has more than 10 experts, doctoral guides, doctors and postgraduates of the provincial thousand person plan. The company has advanced R & D and testing equipment, and is in a leading position in the industry. The company has passed ISO9001, ISO14001, iso45001 and other quality management system certification. Since 2017, national high-tech enterprises Sichuan Carbon World Technology Co., Ltd., Shenzhen Ximai Technology Co., Ltd. and Professor Bao Chenlu, doctoral supervisor of Tianjin University of technology have jointly established Sichuan ximaiwan Technology Co., Ltd. At present, rhino Bay's R & D team and technology reserve belong to the first tier level in China. The Chengdu production base is located in the European industrial city of Qingbaijiang, covering an area of 2500 square meters, with 3 automatic heat conduction silicone, heat conductive silicone grease, heat conducting mud production line, and full testing and testing equipment. R & D and production base of graphene thermal conductive plastics. In 2021, the production and sales center in South China will also be put into operation.

Adhering to the concept of "quality first, customer-oriented", we provide more personalized support and services, become a professional solution center for thermal interface materials, and cooperate with customers for win-win and common growth.Xi Mai Wan Technology Co. , Ltd. is a research and development, manufacturing, sales as one of the new material technology companies. For the demand of high quality thermal management in the fields of chip, communication, security, home appliance, automobile, light source, power supply, architecture, integrated circuit, weapon equipment, etc. , to provide customers with industry-leading thermal management products and technica l services such as heat conduction, heat storage, heat dissipation, temperature regulation, energy saving, etc. .

Contact Person:Junli Fu

Telephone:+86 18628237290

Email:348889136@qq.com